24 years of professional research and development, production of chemical silicone products

Mail

[email protected]

Call Us

+86 18986360854

Construction additive solid powder defoamer

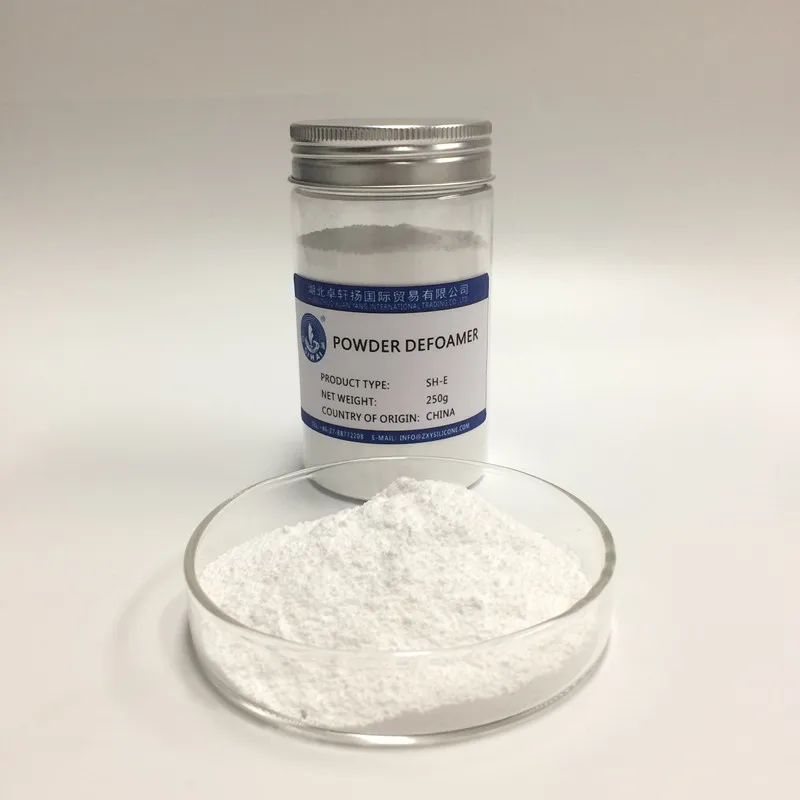

Construction additive solid powder defoamer SH-E

Product Description

Construction additive solid powder defoamer

MAIN COMPOSITION:

a) Liquid hydrocarbon, hydrophobic particles;

b) It is especially suitable for defoaming of cement self-leveling, cement mortar and cement concrete admixture;

Technical Index:

|

Item |

Index |

Test Method |

|

Appearance |

white powder |

By Eye |

|

PH |

6.0-8.0 |

Precision pH test paper (1% aqueous solution) |

|

Active content |

50% |

--- |

|

Note: The above data is for reference only and is not intended as a technical indicator |

||

Superior Properties and Advantages

powder antifoam/defoamer is mainly designed for the foaming characteristics of cement mortar mixing process. The use of cement mortar defoamer can effectively control the foam generation in the cement mortar system, making the concrete components more dense and bright. It helps the combination of the carrier and the foaming system, is easy to disperse into the foaming system, and combines the two, has a low surface tension, contributes to the suppression of foaming, and can reduce the cost.

1. Fast defoaming speed, long foam suppression time, high temperature resistance and strong alkali resistance

2, good dispersion in cement mortar system, does not affect product firmness

3, does not affect the product's water reduction rate, does not affect product quality

4, very strong stability, especially suitable for defoaming and foam suppression under alkaline conditions

5. Low dosage and high efficiency.

6. Increase the strength and brightness of concrete members

7. This product is non-toxic and odorless, which is conducive to production safety.

How to use

1. The recommended use of SH_E_550 is to add water to the concrete after mixing with the additive. The addition of it will reduce the bubbles in the system.

2. The SH_E_550 defoamer has a flowing property and is well matched with the powder coating. Suitable for

caulking agent, interior and exterior wall putty, with certain versatility; the addition amount is 0.1-0.5%;

Application

1. defoamer for concrete admixture

2. antifoam agent for cement self-leveling,

3. defoaming agent for cement mortar and cement concrete

4. defoamer for powder gypsum plaster

5. antifoam agent for Interior and exterior wall putty, caulking agent, gypsum prefabricated board

Package and Storage

This product is packed in 50L paper drums or customized according to customer requirements. Store at 5-35 °C to avoid direct heating. If it is burning on fire, extinguish the fire according to the general petroleum product method. 2. At 10~30°C, under the condition of unopened packaging, the shelf life is 12 months from the date of production.

Model: SH-E Construction additive solid powder defoamer

Certification: SGS SKS BRC

Supply Capacity: 500 Tons each month

Package: Be packed in clean, dry iron drums and sealed